Myco-metallurgy: Engineering Fungal Networks for the Selective Bio-extraction of Rare Earth Elements from E-Waste

The exponential growth of consumer electronics has engendered a parallel crisis: a burgeoning mountain of electronic waste (e-waste) laden with both toxic materials and valuable metals. Within this waste stream lies a particularly critical resource: rare earth elements (REEs), which are indispensable for modern technologies ranging from smartphones and electric vehicles to wind turbines. Conventional methods for recovering REEs, such as pyrometallurgy and hydrometallurgy, are energy-intensive, environmentally hazardous, and economically challenging. This has catalyzed a search for sustainable and efficient alternatives. A novel and highly promising frontier is emerging at the intersection of mycology and metallurgy: myco-metallurgy. This field proposes to harness the natural metabolic and structural properties of fungi to create living, self-replicating bio-factories for the selective extraction and concentration of REEs from complex waste streams like e-waste. By engineering fungal mycelial networks, we can potentially design low-cost, low-energy, and environmentally benign systems for urban mining, transforming a global waste problem into a strategic resource opportunity.

This article explores the scientific basis and speculative potential of engineering fungal networks for REE bio-extraction. We will review the innate capabilities of various fungal species to absorb and mineralize metals, discuss the potential for engineering these natural processes for enhanced selectivity and efficiency, and propose a conceptual framework for a myco-metallurgical recovery system. This approach not only offers a path toward a circular economy for critical materials but also represents a paradigm shift in how we approach resource recovery, moving from harsh chemical processing to sophisticated, biologically-driven solutions.

Fungal Mechanisms of Metal Sequestration

Fungi have evolved sophisticated mechanisms to interact with and accumulate metals from their environment, primarily for nutrient acquisition and detoxification. These natural processes form the foundation of myco-metallurgy. Research has identified several key mechanisms, including biosorption, bioaccumulation, and biomineralization. Biosorption involves the passive binding of metal ions to the fungal cell wall, which is rich in polymers like chitin, chitosan, and glucans that contain functional groups (carboxyl, hydroxyl, phosphate) capable of chelating metallic cations. This process is rapid and can occur even in non-living biomass. For instance, studies on Aspergillus terreus have demonstrated its ability to selectively adsorb Yttrium (Y(III)) from solutions also containing Strontium (Sr(II)), highlighting the potential for selective REE capture (Abdel-Galil et al., 2024).

Beyond surface binding, fungi can actively transport and store metals intracellularly, a process known as bioaccumulation. This metabolically-driven process allows for higher concentration factors than biosorption alone. An even more profound mechanism is biomineralization, where fungi precipitate metals into stable mineral forms. A striking example is the acidophilic fungus Penidiella sp. strain T9, which was found to accumulate dysprosium (Dy) by forming an amorphous dysprosium phosphate (DyPO4) layer directly on its cell surface (Horiike et al., 2018). This ability to transform dissolved ions into solid minerals is particularly advantageous for recovery, as it concentrates the target element into a harvestable form.

Further research into specific fungal strains has revealed remarkable specialization. Penicillium sp. ZD28, isolated from a rare earth mining area, demonstrated an exceptional capacity to accumulate yttrium, removing up to 99% of the element from a solution during its growth phase (Wang et al., 2020). This suggests that fungi from metal-rich environments may be naturally adapted for high-efficiency uptake and represent a valuable genetic resource for developing targeted myco-metallurgical processes. These findings collectively demonstrate that fungi possess a diverse toolkit for metal interaction, offering multiple avenues for exploitation in a bio-extraction context.

Engineering Mycelial Networks for Industrial Application

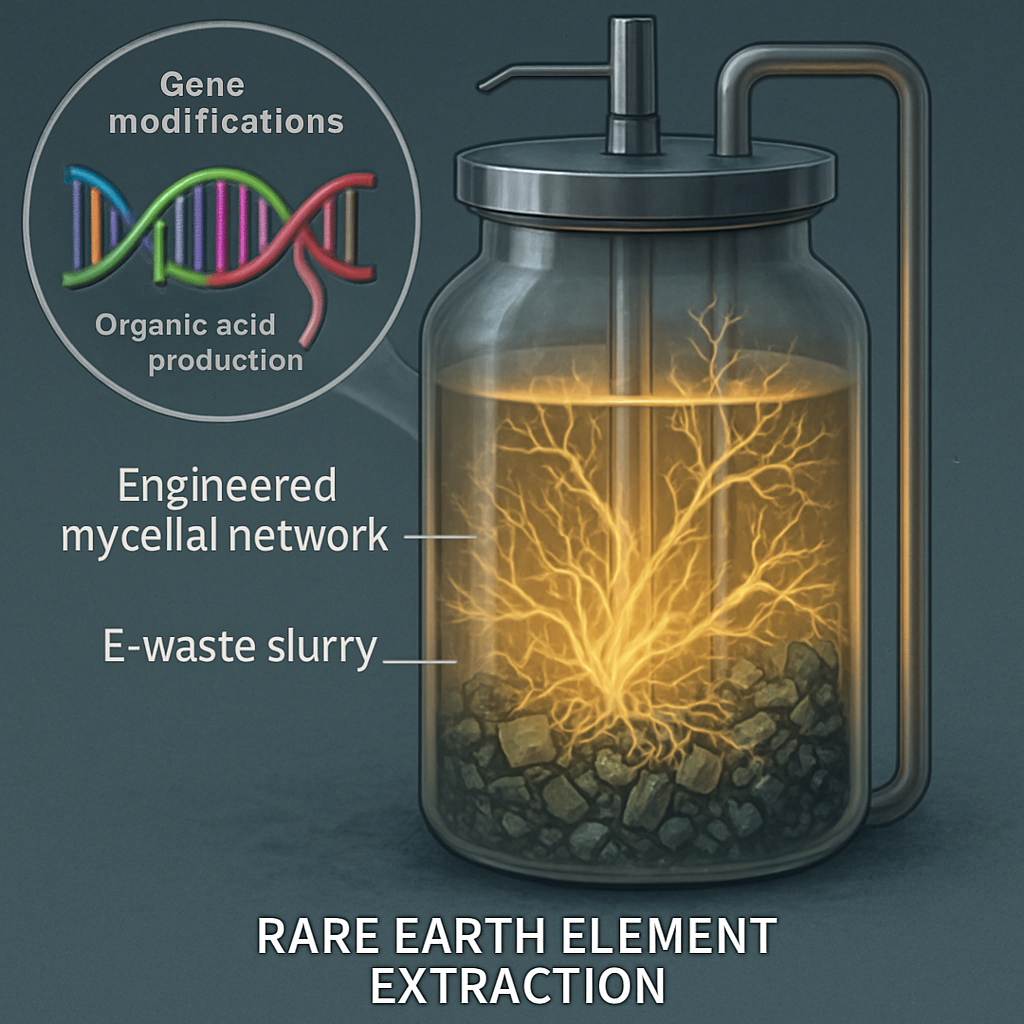

The true potential of myco-metallurgy lies not in using dispersed fungal cells, but in harnessing the power of the mycelial network—the vast, interconnected web of hyphae that constitutes the main body of a fungus. These networks are natural exploration and transportation systems, perfectly suited to permeate and colonize a substrate like crushed e-waste. The vision is to engineer these networks as dynamic, three-dimensional scaffolds for REE extraction. In a potential industrial process, shredded e-waste would be introduced into a bioreactor, possibly an airlift bioreactor (ALR) which is known to be gentle on fungal structures, thereby promoting extensive mycelial growth (Cerrone & O’Connor, 2025).

To enhance the natural capabilities of these fungi, genetic and metabolic engineering techniques can be applied. Drawing inspiration from the engineering of bacteria for bioremediation (Sharma et al., 2024), key fungal genes could be targeted. For example, one could overexpress genes responsible for producing specific organic acids (e.g., citric, oxalic acid) that are known to leach metals from solid matrices. Simultaneously, genes encoding for metal transporters or specific metal-binding proteins (metallothioneins) could be upregulated to increase the specificity and uptake rate for high-value REEs like neodymium and dysprosium. The goal would be to create a fungal strain that actively "mines" the e-waste, dissolving REEs and selectively pulling them into its own biomass.

Furthermore, the process can be designed to be circular. After the fungal network has become saturated with REEs, the biomass can be harvested. The entrapped metals could then be released using a mild acid wash, regenerating the fungal biomass for another cycle or processing it to recover the concentrated metals. The organism of choice, such as Penicillium simplicissimum, which has shown promise in biomining lunar regolith, could be adapted for this purpose (Figueira et al., 2025). This integrated "leach-absorb-harvest" system, powered by self-replicating and engineered fungal networks, presents a scalable and sustainable alternative to the brute-force chemical methods currently in use.

A Conceptual Myco-metallurgical Process for E-Waste

Integrating these concepts, we can outline a hypothetical myco-metallurgical workflow. The process would begin with the mechanical preparation of e-waste, involving shredding and grinding to increase the surface area for fungal interaction. This powdered e-waste is then sterilized and introduced as a slurry into a large-scale bioreactor. A carefully selected and potentially genetically engineered fungal species, such as a specialized Penicillium or Aspergillus strain, is inoculated into the slurry.

Inside the bioreactor, the fungus grows, extending its mycelial network throughout the e-waste matrix. The fungus secretes a cocktail of organic acids and chelating agents, creating a bioactive leachate that solubilizes REEs from the solid waste particles. As these REE ions become available in the aqueous phase, they are selectively captured by the fungal biomass through a combination of biosorption on the cell walls and active bioaccumulation into the hyphae. This process transforms the dispersed, low-concentration REEs into a concentrated, mobile form within the fungal network.

After an incubation period optimized for maximum uptake, the REE-laden fungal biomass is separated from the now-depleted e-waste residue. This separation could be achieved through filtration or flotation. The harvested biomass, now effectively a "bio-ore," is then subjected to a metal recovery step. This could involve incineration to produce a concentrated metal ash or, more sustainably, a chemical stripping process using a weak acid to release the REEs back into a clean solution for final precipitation and purification. This conceptual process leverages biological precision to overcome the economic and environmental barriers of traditional recycling, creating a closed-loop system for critical resource recovery.

Conclusion

Myco-metallurgy represents a transformative, albeit nascent, approach to addressing the critical challenges of e-waste management and rare earth element scarcity. By leveraging the innate and engineered capabilities of fungal networks, it is possible to envision a future where urban mines are operated not with harsh chemicals and high heat, but with self-replicating, selective biological systems. The primary advantages are clear: significantly lower energy consumption, reduced reliance on toxic reagents, and the potential to turn a hazardous waste liability into a valuable resource stream, aligning perfectly with the principles of a circular economy. The findings that fungi like Penicillium sp. and Penidiella sp. can naturally accumulate specific REEs provide a strong proof-of-concept for this approach.

However, significant research is required to translate this concept into an industrial reality. Key open questions remain: How can we enhance the selectivity of fungi to target the most economically critical REEs (e.g., neodymium, dysprosium, terbium) over more common metals found in e-waste? What are the optimal bioreactor conditions (pH, aeration, nutrient levels, e-waste pulp density) to maximize fungal growth and metal uptake simultaneously? A critical challenge will be the development of efficient, non-destructive methods for recovering the accumulated metals from the fungal biomass, ideally allowing the mycelium to be recycled.

Future research should focus on high-throughput screening of novel fungal species from metal-contaminated environments, applying advanced genetic engineering tools to create "specialist" REE-mining strains, and pilot-scale studies to test the feasibility and economics of the proposed myco-metallurgical workflow. By bridging the gap between microbiology, materials science, and engineering, myco-metallurgy could unlock a truly sustainable solution for recovering the essential elements of our technological future.

References

- Abdel-Galil, E. A., Kandeel, E. M., Kasem, A. E., Mohamed, M. K., & Mahrous, S. S. (2024). Biosorption and separation behaviour of Sr(II) and Y(III) using Aspergillus terreus: isolation, characterization, batch and column studies. International Journal of Environmental Science and Technology. https://doi.org/10.1007/s13762-024-05906-z

- Binnemans, K., & Jones, P. T. (2025). Lindy Effect in Hydrometallurgy. Journal of Sustainable Metallurgy. https://doi.org/10.1007/s40831-025-01119-x

- Cerrone, F., & O’Connor, K. E. (2025). Cultivation of filamentous fungi in airlift bioreactors: advantages and disadvantages. Applied Microbiology and Biotechnology. https://doi.org/10.1007/s00253-025-13422-4

- Figueira, J., Koch, S., Müller, D. W., Slawik, S., Cowley, A., Moeller, R., & Cortesão, M. (2025). Biomining of lunar regolith simulant EAC-1A with the fungus Penicillium simplicissimum. Fungal Biology and Biotechnology. https://doi.org/10.1186/s40694-025-00201-z

- Heydarian, A., Vakilchap, F., Mousavi, S. N., & Mousavi, S. M. (2025). Bacterial acidic agents-assisted multi-elemental (Ni, Co, and Li) leaching of used lithium-ion batteries at high pulp densities. Scientific Reports. https://doi.org/10.1038/s41598-025-00660-9

- Horiike, T., Kiyono, H., & Yamashita, M. (2018). Dysprosium Biomineralization by Penidiella sp. Strain T9. In Biomineralization (pp. 317-327). Springer, Singapore. https://doi.org/10.1007/978-981-13-1002-7_26

- Khan, S., Alam, F. S., & Borah, D. (2024). Microbial cell factories in the remediation of e-wastes: an insight. Biotechnology for the Environment. https://doi.org/10.1186/s44314-024-00003-4

- Oke, E. A., & Potgieter, H. (2024). Discarded e-waste/printed circuit boards: a review of their recent methods of disassembly, sorting and environmental implications. Journal of Material Cycles and Waste Management. https://doi.org/10.1007/s10163-024-01917-7

- Sharma, S., Pathania, S., Bhagta, S., Kaushal, N., Bhardwaj, S., Bhatia, R. K., & Walia, A. (2024). Microbial remediation of polluted environment by using recombinant E. coli: a review. Biotechnology for the Environment. https://doi.org/10.1186/s44314-024-00008-z

- Tezyapar Kara, I., Kremser, K., Wagland, S. T., & Coulon, F. (2023). Bioleaching metal-bearing wastes and by-products for resource recovery: a review. Environmental Chemistry Letters. https://doi.org/10.1007/s10311-023-01611-4

- Wang, W., Xu, C., Jin, Y., Zhang, Z., Yan, R., & Zhu, D. (2020). The accumulation of rare-earth yttrium ions by Penicillium sp. ZD28. AMB Express. https://doi.org/10.1186/s13568-020-0961-8