Microbial Fuel Cells for Wastewater Treatment

Microbial Fuel Cells (MFCs) represent a promising bioelectrochemical technology that simultaneously treats wastewater and recovers energy in the form of electricity. By harnessing the metabolic activity of specific microorganisms (electrogens), MFCs oxidize organic matter present in wastewater, transferring the released electrons to an anode. These electrons then flow through an external circuit to a cathode, where they combine with an electron acceptor (typically oxygen) and protons to form water, generating an electrical current. This dual function addresses two major global challenges: water pollution and the need for sustainable energy sources.

The growing interest in MFCs stems from their potential to significantly reduce the energy footprint of conventional wastewater treatment plants, which are often energy-intensive. Furthermore, MFCs offer possibilities for nutrient recovery and the removal of specific pollutants that are challenging for traditional methods. This article provides an overview of the fundamental principles of MFC operation in wastewater treatment, discusses key factors influencing their performance, explores various applications and integration strategies, and concludes with the challenges and future prospects of this innovative technology.

Principles of MFC Operation in Wastewater Treatment

At the heart of an MFC is the bioelectrocatalytic activity of electrogenic bacteria. These microbes colonize the anode surface, forming a biofilm. In the anaerobic environment of the anode chamber, they metabolize organic compounds (the fuel) present in the wastewater, such as carbohydrates, proteins, and volatile fatty acids (VFAs). During this oxidation process, electrons are released. Electrogens possess unique mechanisms for extracellular electron transfer (EET), allowing them to shuttle these electrons outside their cells to the solid anode electrode. Common EET mechanisms include direct contact via outer-membrane cytochromes or conductive protein filaments (nanowires), or indirect transfer via self-produced soluble electron mediators.

The anode, typically made of carbon-based materials like graphite, carbon cloth, or carbon felt due to their conductivity, chemical stability, and biocompatibility, serves as the electron acceptor for the bacteria. The collected electrons travel through an external electrical circuit, creating a current, towards the cathode. The cathode, often separated from the anode by a proton exchange membrane (PEM) or a salt bridge to maintain charge balance and prevent oxygen diffusion to the anaerobic anode, facilitates the reduction reaction. In the most common configuration, oxygen from the air acts as the terminal electron acceptor. At the cathode surface, electrons combine with protons (which migrate from the anode chamber) and oxygen to produce water (O2 + 4e- + 4H+ → 2H2O). The overall process effectively converts chemical energy stored in wastewater organics into electrical energy while simultaneously reducing the organic load (Chemical Oxygen Demand - COD) of the wastewater.

Performance and Optimization Factors

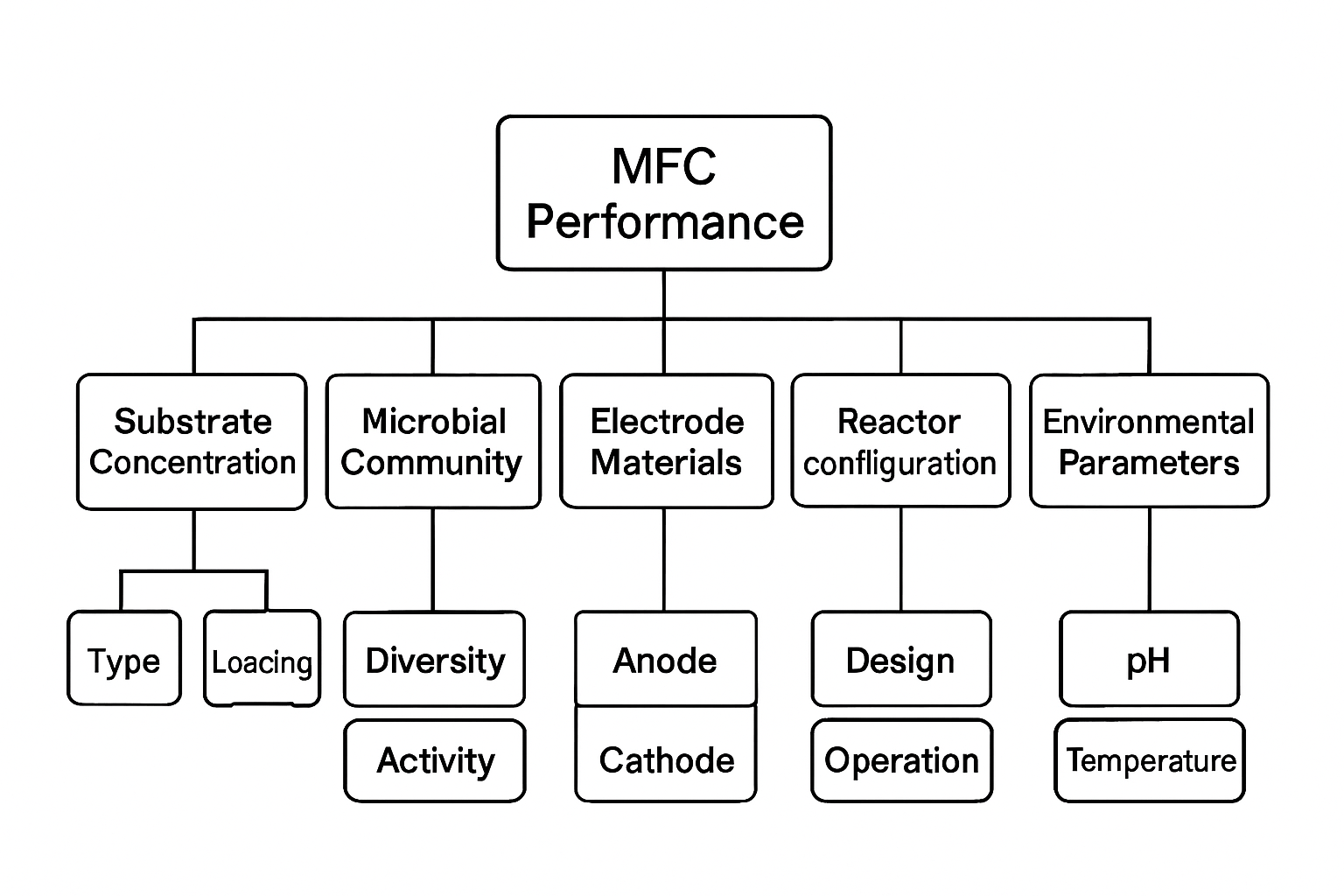

The efficiency of MFCs in treating wastewater and generating electricity is influenced by a complex interplay of biological, chemical, and engineering factors. The composition and concentration of the wastewater (substrate) are critical; higher organic loading rates (OLR) generally lead to higher current generation up to a certain point, beyond which mass transfer limitations or inhibition may occur. The microbial community structure within the anode biofilm is paramount. While pure cultures of known electrogens (e.g., Geobacter, Shewanella) are studied, mixed consortia naturally present in wastewater often result in more robust and adaptable systems capable of degrading complex substrates, though community dynamics can be hard to control.

Electrode materials significantly impact performance. Anode materials require high conductivity, large surface area for biofilm growth, good mechanical strength, corrosion resistance, and low cost. Modifications like surface treatments or incorporating nanomaterials can enhance biofilm adhesion and electron transfer rates. Cathode performance, particularly the oxygen reduction reaction (ORR), is often a limiting factor due to slow kinetics. While precious metal catalysts (like platinum) are effective, their high cost drives research into alternatives such as activated carbon, manganese oxides, or biocathodes employing microbial catalysts. Reactor configuration (e.g., two-chamber vs. single-chamber air-cathode designs), electrode spacing, hydraulic retention time (HRT), internal and external resistance, pH, and temperature are crucial engineering and operational parameters that must be optimized to maximize both treatment efficiency and power output.

Applications and Integration Strategies

Beyond the primary goals of COD removal and electricity generation, MFC technology demonstrates potential in various specialized wastewater treatment applications. Certain MFC configurations can facilitate nutrient removal. For instance, nitrogen can be removed through coupled nitrification-denitrification processes integrated within the MFC system, potentially utilizing the cathode as an aerobic zone for nitrification or exploiting denitrifying bacteria capable of EET. Phosphorus can be recovered as struvite, with MFCs potentially helping to control the required pH conditions or provide energy for recovery processes. MFCs have also shown promise in degrading recalcitrant organic micropollutants, such as pharmaceuticals and endocrine disruptors, which are poorly removed by conventional methods. The unique redox environments created within MFCs can enhance the biotransformation of these persistent compounds.

Furthermore, the electrical signal generated by MFCs directly correlates with the metabolic activity of the anode biofilm, which in turn depends on the substrate concentration. This allows MFCs to function as self-powered biosensors for real-time monitoring of wastewater quality parameters like COD or biochemical oxygen demand (BOD), potentially serving as early warning systems for pollution events or process upsets. Integration with other treatment technologies is an active area of research. For example, Constructed Wetland-MFCs (CW-MFCs) combine the principles of MFCs with the natural treatment processes of constructed wetlands, potentially enhancing pollutant removal and generating power in decentralized settings. Coupling MFCs with Microbial Electrolysis Cells (MECs) or Anaerobic Digestion (AD) can further enhance resource recovery, producing hydrogen gas or methane, respectively.

Conclusion

Microbial Fuel Cells offer a compelling vision for the future of wastewater treatment, transforming pollutants into resources (electricity and treated water) and potentially reducing the significant energy demands of sanitation infrastructure. The core principles rely on harnessing microbial metabolism for direct electricity generation coupled with organic matter degradation. Significant progress has been made in understanding the underlying bioelectrochemical processes, developing novel materials, and optimizing reactor designs. Applications extend beyond basic COD removal to nutrient management, micropollutant degradation, and biosensing.

Despite their promise, challenges remain before MFCs can be widely implemented at scale. Key hurdles include relatively low power densities compared to other energy technologies, the high cost of some components (like membranes and catalysts), long-term operational stability, and efficient scale-up. Future research should focus on developing cost-effective and durable electrode materials, engineering robust microbial consortia optimized for specific wastewaters, improving reactor architecture for better mass transfer and lower internal resistance, and demonstrating long-term performance in real-world, large-scale applications. Continued innovation in materials science, microbial ecology, and bioengineering will be crucial to unlocking the full potential of MFCs for sustainable wastewater management.

References

- Hartl, M., García-Galán, M. J., Matamoros, V., Fernández-Gatell, M., Rousseau, D. P. L., Du Laing, G., Garfí, M., & Puigagut, J. (2021). Constructed wetlands operated as bioelectrochemical systems for the removal of organic micropollutants. arXiv:2101.05522v1 [q-bio.QM]

- Corbella, C., Hartl, M., Fernandez-gatell, M., & Puigagut, J. (2020). MFC-based biosensor for domestic wastewater COD assessment in constructed wetlands. arXiv:2003.14078v1 [q-bio.QM] (DOI: 10.1016/j.scitotenv.2018.12.347)

- Hartl, M., Bedoya-Ríos, D. F., Fernández-Gatell, M., Rousseau, D. P. L., Du Laing, G., Garfí, M., & Puigagut, J. (2020). Contaminants removal and bacterial activity enhancement along the flow path of constructed wetland microbial fuel cells. arXiv:2003.08896v1 [q-bio.QM] (DOI: 10.1016/j.scitotenv.2018.10.234)

- Preen, R. J., You, J., Bull, L., & Ieropoulos, I. A. (2016). Design Mining Microbial Fuel Cell Cascades. arXiv:1610.05716v2 [cs.NE] (DOI: 10.1007/s00500-018-3117-x)

- de Lichtervelde, A. C. L., ter Heijne, A., Hamelers, H. V. M., Biesheuvel, P. M., & Dykstra, J. E. (2019). Theory of Ion and Electron Transport Coupled with Biochemical Conversions in an Electroactive Biofilm. arXiv:1912.11127v1 [physics.chem-ph] (DOI: 10.1103/PhysRevApplied.12.014018)

- Arashiro, L. T., Ferrer, I., Rousseau, D. P. L., Van Hulle, S. W. H., & Garfi, M. (2020). The effect of primary treatment of wastewater in high rate algal pond systems: biomass and bioenergy recovery. arXiv:2003.06188v1 [q-bio.QM] (DOI: 10.1016/j.biortech.2019.01.096)

- Piercy, E., Sun, X., Ellis, P. R., Taylor, M., & Guo, M. (2025). Temporal Dynamics of Microbial Communities in Anaerobic Digestion: Influence of Temperature and Feedstock Composition on Reactor Performance and Stability. arXiv:2501.06800v1 [q-bio.QM]

- Taylor, J., Rapaport, A., & Dochain, D. (2021). Convex optimization of bioprocesses. arXiv:2107.01843v1 [math.OC]

- Arashiro, L. T., Montero, N., Ferrer, I., Acien, F. G., Gomez, C., & Garfi, M. (2020). Life Cycle Assessment of high rate algal ponds for wastewater treatment and resource recovery. arXiv:2003.06194v1 [q-bio.QM] (DOI: 10.1016/j.scitotenv.2017.12.051)

- Mohammadi, E., Ortiz-Arroyo, D., Hansen, A. A., Stokholm-Bjerregaard, M., Gros, S., Anand, A. S., & Durdevic, P. (2024). Application of Soft Actor-Critic Algorithms in Optimizing Wastewater Treatment with Time Delays Integration. arXiv:2411.18305v1 [eess.SY] (DOI: 10.1016/j.eswa.2025.127180)

- Mohammadi, E., Rani, A., Stokholm-Bjerregaard, M., Ortiz-Arroyo, D., & Durdevic, P. (2024). Wastewater Treatment Plant Data for Nutrient Removal System. arXiv:2407.05346v1 [eess.SY]