Liquid Metal Morphing Antennas for Resilient Ad-Hoc Networks in Austere Communication Environments

Liquid metal morphing antennas hold significant promise for enhancing the resilience of ad-hoc networks, particularly in austere communication environments where conventional infrastructure is damaged, absent, or unreliable. This article delves into the emerging field of liquid metal antennas, exploring their unique properties, fabrication techniques, and the transformative impact they can have on establishing robust and adaptable communication links.

The core advantage of liquid metal antennas lies in their ability to be dynamically reconfigured – changing their shape, and consequently their frequency, polarization, and radiation patterns – in response to changing network demands or environmental conditions. This morphing capability is crucial for ad-hoc networks, which are often characterized by mobile nodes, unpredictable topologies, and fluctuating channel characteristics. Gallium-based alloys, such as Eutectic Gallium-Indium (EGaIn) and Galinstan, are particularly favored due to their low toxicity, high conductivity, and fluidity at or near room temperature. This allows for the creation of antennas that can be injected into microfluidic channels, 3D printed into complex geometries, or integrated into stretchable and flexible substrates.

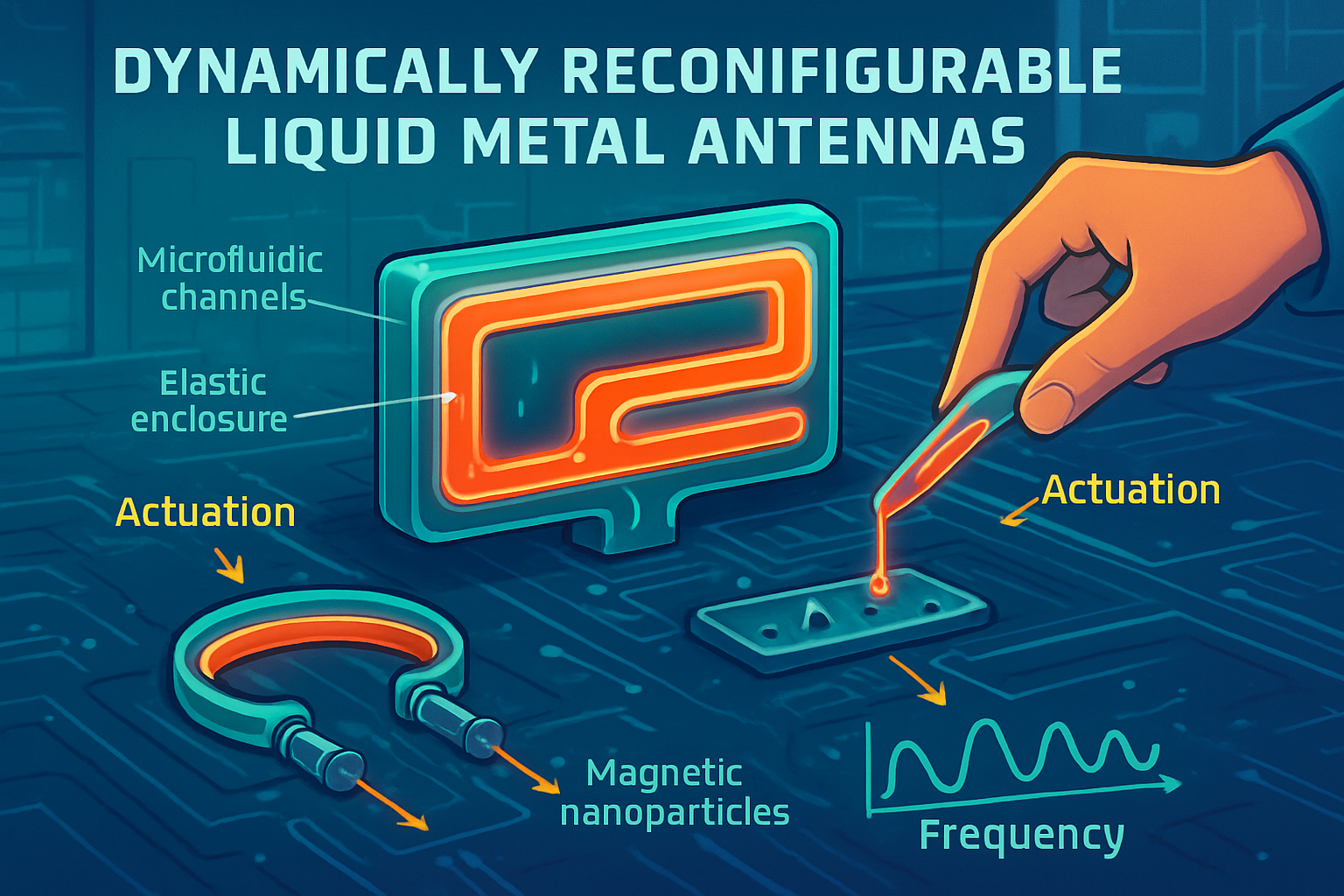

Dynamically Reconfigurable Liquid Metal Antennas

The ability to alter an antenna's physical structure translates directly to its electromagnetic properties. For instance, by controlling the flow and distribution of liquid metal within predefined channels or elastic enclosures, parameters like resonant frequency can be tuned over a wide range. This is invaluable in austere environments where spectral interference may be high, or where different frequency bands need to be opportunistically exploited. Research has demonstrated various actuation mechanisms, including hydraulic or pneumatic pressure, electroosmotic flow, and even magnetic manipulation when liquid metals are compounded with magnetic nanoparticles. These methods allow for rapid and repeatable changes in antenna geometry, enabling functions like beam steering to establish directional links, frequency hopping to evade jamming, and impedance matching for optimal power transfer in diverse conditions.

The integration of liquid metals with soft robotics and stretchable electronics further expands the possibilities. Antennas can be embedded in deformable structures that can be deployed, stowed, or even self-heal, offering unprecedented resilience. For example, a morphing antenna could be integrated into the wing of a drone operating in a disaster zone, reconfiguring itself to maintain optimal communication links as the drone navigates complex terrain. Similarly, wearable antennas for first responders could adapt their characteristics based on the user's posture or proximity to other network nodes. The core challenge here lies in developing robust encapsulation methods to prevent leakage and oxidation of the liquid metal while maintaining flexibility and ensuring consistent electrical contact.

Fabrication and Integration Challenges for Resilient Networks

While the concept of liquid metal morphing antennas is compelling, several fabrication and integration challenges must be addressed for their practical deployment in resilient ad-hoc networks. Creating complex, multi-layered microfluidic systems that can precisely control the liquid metal's shape and position while enduring mechanical stress and environmental extremes (e.g., temperature fluctuations, vibrations) is a significant hurdle. Techniques such as suspension printing of liquid metal in yield-stress fluids show promise for creating 3D liquid metal constructs with high fidelity, which could lead to more robust and complex antenna designs.

Furthermore, integrating these antennas with control systems and sensor feedback is crucial for autonomous operation. For an ad-hoc network to be truly resilient, its constituent antennas must be able to sense the communication environment (e.g., signal strength, interference levels, network topology) and adapt their configurations accordingly without manual intervention. This necessitates the development of compact, low-power control electronics and sophisticated algorithms that can manage the dynamic reconfiguration process. The inherent deformability also presents challenges in maintaining stable electrical connections between the liquid metal and the rigid components of the transceiver circuitry, an area where stretchable solder and advanced interconnect technologies are being explored.

Towards Self-Healing and Environmentally Adaptive Communication Systems

A particularly exciting frontier is the development of self-healing liquid metal antennas. If a segment of the antenna is damaged, the fluidic nature of the liquid metal could allow it to flow and re-establish a conductive path, or alternate pathways could be activated. This intrinsic resilience is highly desirable for networks operating in contested or disaster-stricken areas where physical damage to equipment is likely. Imagine a network of sensors scattered in a hazardous environment; if some antenna elements are crushed or broken, the network could potentially re-route communication through undamaged or self-repaired elements, maintaining operational integrity.

Moreover, the adaptability of liquid metal antennas extends beyond simple reconfiguration. There is potential for creating antennas that can sense and respond to their immediate physical environment. For instance, an antenna could change its shape to shed ice in cold climates or alter its radiation pattern to minimize absorption by dense foliage. The integration of liquid metal with functional polymers and composites could lead to "intelligent" materials that assist with perception and responsivity, further enhancing the antenna's ability to adapt and survive in austere conditions. The ultimate vision is a truly autonomous and resilient communication system where the antennas are not just passive radiators but active, adaptive components of the network.

Conclusion

Liquid metal morphing antennas offer a paradigm shift for ad-hoc networks in austere environments, promising unprecedented levels of adaptability, resilience, and dynamic performance. Their ability to change form and function on demand addresses many limitations of traditional fixed-geometry antennas, paving the way for more robust communication systems in challenging scenarios ranging from disaster relief and remote sensing to defense applications and space exploration.

Future research will likely focus on several key areas:

- Advanced Fabrication: Developing scalable and reliable manufacturing techniques for complex 3D liquid metal antenna structures, including robust encapsulation and interconnection methods.

- Autonomous Control: Creating sophisticated control algorithms and integrated sensing capabilities that enable antennas to autonomously adapt to dynamic electromagnetic environments and network requirements.

- Multi-Functional Integration: Combining liquid metal antennas with other functionalities, such as energy harvesting, sensing, or even structural load-bearing, within a single morphable platform.

- Material Innovation: Exploring new liquid metal alloys and composites with enhanced properties (e.g., higher conductivity, lower viscosity, improved stability) and investigating self-healing mechanisms.

- Network-Level Optimization: Developing protocols and strategies that can fully exploit the reconfigurability of liquid metal antennas at the network level to maximize overall resilience and performance.

Open problems include achieving long-term stability and reliability of liquid metal structures under harsh operational conditions, mitigating potential electromagnetic interference caused by rapid reconfigurations, and developing accurate and efficient electromagnetic modeling techniques for these dynamically changing structures. Addressing these challenges will unlock the full potential of liquid metal morphing antennas, ushering in an era of truly resilient and adaptive ad-hoc networks capable of operating effectively in the most demanding communication landscapes.

References

- Choi, C., Liu, L., & Hwang, B. (2025). Liquid metal composites: Recent advances and applications. International Journal of Minerals, Metallurgy and Materials. https://doi.org/10.1007/s12613-025-3090-1

- Jeong, S. H., Chen, S., Huo, J., Gamstedt, E. K., Liu, J., Zhang, S.-L., Zhang, Z.-B., Hjort, K., & Wu, Z. (2015). Mechanically Stretchable and Electrically Insulating Thermal Elastomer Composite by Liquid Alloy Droplet Embedment. Scientific Reports. https://doi.org/10.1038/srep18257

- Wang, Q., Wang, Z., Yang, Y., Zhang, C., Han, M., Wang, W., & Jin, Y. (2025). A stretchable frequency reconfigurable antenna controlled by compressive buckling for W-band applications. Microsystems & Nanoengineering. https://doi.org/10.1038/s41378-025-00890-x

- Wu, Q., Zhu, F., Wu, Z., Xie, Y., Qian, J., Yin, J., & Yang, H. (2022). Suspension printing of liquid metal in yield-stress fluid for resilient 3D constructs with electromagnetic functions. npj Flexible Electronics. https://doi.org/10.1038/s41528-022-00184-6

- Ai, L., Lin, W., Cao, C., Li, P., Wang, X., Lv, D., Li, X., Yang, Z., & Yao, X. (2023). Tough soldering for stretchable electronics by small-molecule modulated interfacial assemblies. Nature Communications. https://doi.org/10.1038/s41467-023-43574-8

- Zhu, J., Dexheimer, M., & Cheng, H. (2017). Reconfigurable systems for multifunctional electronics. npj Flexible Electronics. https://doi.org/10.1038/s41528-017-0009-6

- Nan, T., Lin, H., Gao, Y., Matyushov, A., Yu, G., Chen, H., Sun, N., Wei, S., Wang, Z., Li, M., Wang, X., Belkessam, A., Guo, R., Chen, B., Zhou, J., Qian, Z., Hui, Y., Rinaldi, M., McConney, M. E., Howe, B. M., Hu, Z., Jones, J. G., Brown, G. J., & Sun, N. X. (2017). Acoustically actuated ultra-compact NEMS magnetoelectric antennas. Nature Communications. https://doi.org/10.1038/s41467-017-00343-8

- Ford, M. J., Ohm, Y., Chin, K., & Majidi, C. (2021). Composites of functional polymers: Toward physical intelligence using flexible and soft materials. Journal of Materials Research. https://doi.org/10.1557/s43578-021-00381-5

- Zhang, Y., Pan, C., Liu, P., Peng, L., Liu, Z., Li, Y., Wang, Q., Wu, T., Li, Z., Majidi, C., & Jiang, L. (2023). Coaxially printed magnetic mechanical electrical hybrid structures with actuation and sensing functionalities. Nature Communications. https://doi.org/10.1038/s41467-023-40109-z

- Xie, X., Xu, Z., Yu, X., Jiang, H., Li, H., & Feng, W. (2023). Liquid-in-liquid printing of 3D and mechanically tunable conductive hydrogels. Nature Communications. https://doi.org/10.1038/s41467-023-40004-7