Computational Gastrophysics: Simulating Flavor Perception and Texture Dynamics in Novel Food Structures

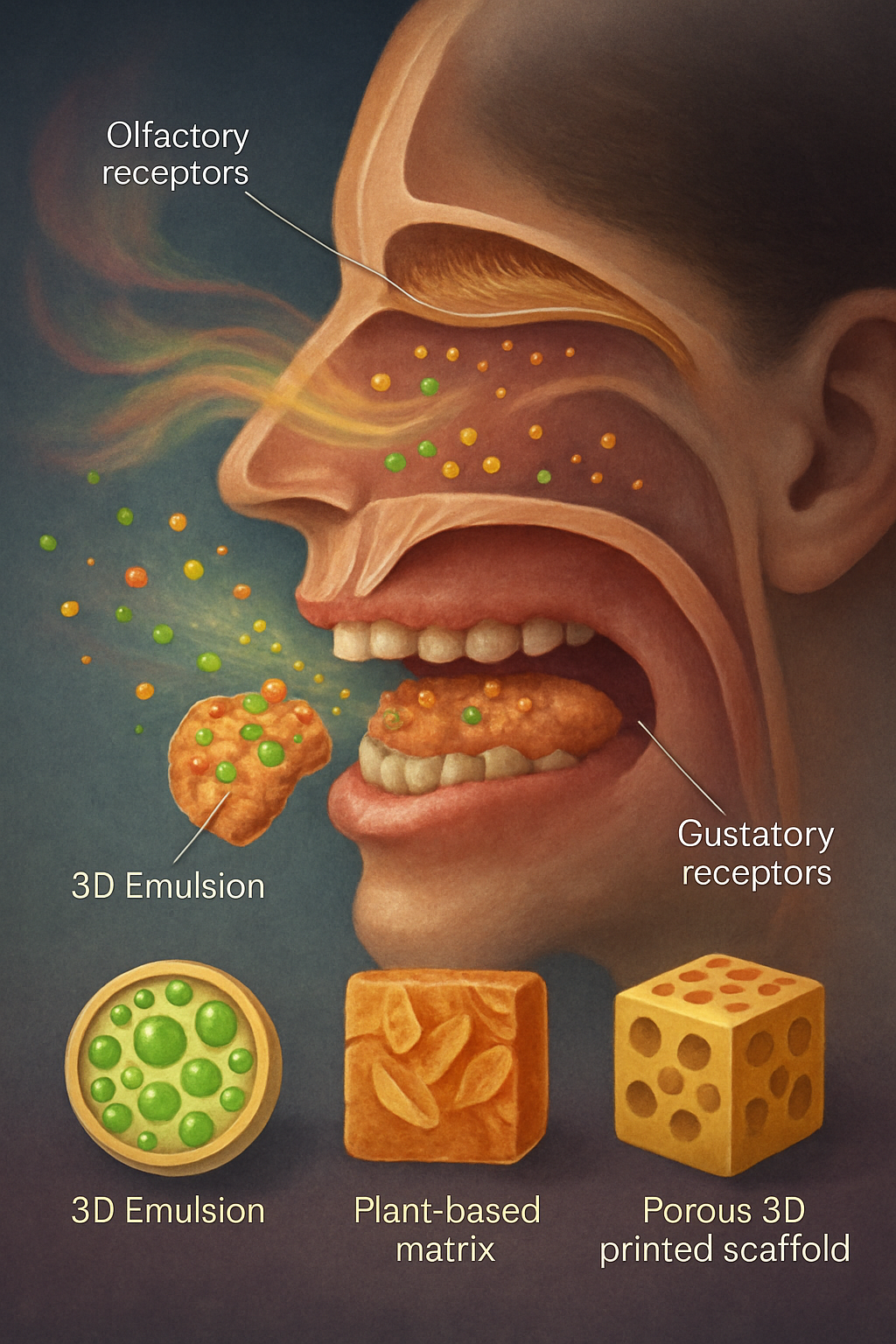

The burgeoning field of computational gastrophysics sits at the nexus of food science, physics, materials science, and computer science, aiming to unravel the complex interplay between the physical structure of food and its sensory perception, encompassing both flavor and texture. As consumer demand for novel food experiences, personalized nutrition, and sustainable food alternatives grows, the ability to predict and design these sensory attributes in silico becomes paramount. Simulating flavor perception involves modeling the release and transport of volatile and non-volatile compounds from the food matrix to olfactory and gustatory receptors, while simulating texture dynamics requires understanding the mechanical breakdown of complex food structures during oral processing and its correlation with mechanoreceptor responses.

This article delves into the cutting-edge advancements in computational gastrophysics, focusing on the simulation of flavor perception and texture dynamics within novel and engineered food structures. We explore how multiscale modeling approaches, ranging from molecular interactions to macroscopic biomechanics, are being employed to create predictive frameworks. The ultimate goal is to accelerate the innovation cycle for new food products, including those derived from 3D food printing, plant-based analogues, and reformulated traditional foods with enhanced nutritional or sensory profiles. We will also speculate on how integrating data from advanced sensory evaluation techniques and artificial intelligence can create a feedback loop, refining these computational models and paving the way for truly "digitally designed" food experiences.

Simulating Flavor Release and Perception: A Multiphysics Challenge

Flavor perception is a complex, multisensory experience initiated by the release of aroma compounds (volatiles) and taste compounds (non-volatiles) from the food matrix during mastication and their subsequent interaction with receptors in the nasal and oral cavities. Computational modeling of this process requires a multiphysics approach, considering factors such as the food's microstructure, the partitioning of flavor molecules between different phases (e.g., water, oil, air), mass transport phenomena (diffusion, convection), and even the influence of saliva and oral temperature. Recent research by Xu et al. (2025) highlights how integrated omics can reveal mechanisms underlying aroma changes in fruit during postharvest storage, providing valuable datasets for model validation.

A key challenge lies in accurately representing the heterogeneous nature of food. For instance, the release of aroma from an emulsion will differ significantly from that of a cellular plant-based material or a porous 3D-printed scaffold (Derossi et al., 2024). Computational fluid dynamics (CFD) coupled with mass transfer models are increasingly used to simulate the spatiotemporal distribution of flavorants in the oral cavity and their transit to olfactory receptors. Wang et al. (2025) explored the molecular structure and pyrolytic volatiles of melanoidins, indicating how specific chemical structures influence aroma profiles, a critical input for flavor release simulations. Future models may need to incorporate the dynamic changes in the food matrix itself during oral processing (e.g., particle size reduction, mixing with saliva) and how these changes modulate flavor release kinetics. The influence of the food matrix on the stability and release of bioactive compounds, as explored by Hamza et al. (2025) in nanoemulsions, also provides analogous principles applicable to flavor compounds.

Modeling Texture Dynamics: From Food Structure Breakdown to Mechanoreception

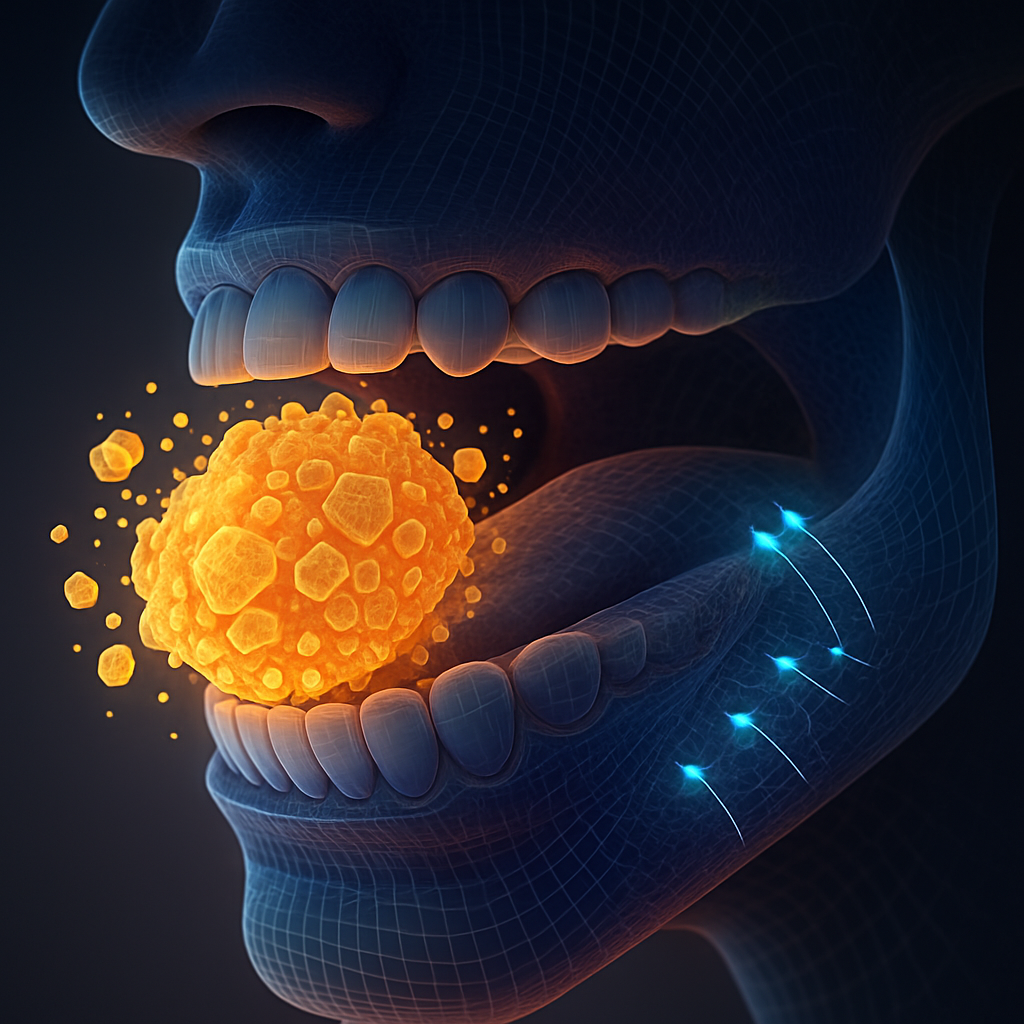

Food texture is perceived through the complex mechanical and physical interactions between the food and the oral environment, including teeth, tongue, palate, and saliva. Simulating texture dynamics involves modeling the deformation and fracture of food structures under applied forces during biting, chewing, and swallowing. Finite Element Analysis (FEA) and Discrete Element Method (DEM) are powerful tools for predicting how a food's macroscopic structure (e.g., porosity, component arrangement) and the material properties of its constituents (e.g., elasticity, viscosity, fracture strength) dictate its breakdown behavior. Ransmark et al. (2025) reviewed the break-up of plant cell structures in high-pressure homogenizers, providing insights into material deformation relevant to oral processing.

A significant frontier in texture simulation is linking these mechanical breakdown models to actual sensory perception. This requires understanding how the evolving food bolus stimulates mechanoreceptors in the oral cavity. For example, the sensation of "crunchiness" or "creaminess" arises from specific patterns of force, deformation, and particle size distribution over time. Recent advancements in biomimetic artificial mouths, such as the one developed by Avila-Sierra et al. (2024), which reproduces oral processing of soft foods, offer invaluable platforms for validating and refining computational models of food breakdown and bolus formation. Liu et al. (2025) surveyed the evolution of mastication evaluation, including AI-driven approaches, which can provide quantitative data to correlate with simulation outputs. The work by Ghosheh et al. (2024) on metamaterial-based injection molding for meat analogs demonstrates the importance of controlling multi-scale structures to mimic desired textural properties, a process that could be guided by predictive simulations.

Integrating Computational Models with Novel Food Design and Manufacturing

The ultimate promise of computational gastrophysics lies in its potential to guide the design and manufacturing of novel food structures with tailored flavor and texture profiles. For instance, 3D food printing allows for precise control over macro- and microstructure, offering a fertile ground for applying predictive models (Derossi et al., 2024). Imagine designing a food with a specific flavor release profile by computationally optimizing pore connectivity or a plant-based steak with a desired bite force and fiber alignment through simulation-driven material selection and printing paths (Ghosheh et al., 2024). Integrating AI and machine learning can further accelerate this process by learning complex structure-property-perception relationships from large datasets generated by simulations and sensory experiments (Siddique et al., 2025).

However, significant challenges remain. Accurately parameterizing models with the diverse and often ill-defined properties of food materials is non-trivial. Capturing the full complexity of human sensory perception, which is influenced by individual physiology, prior experience, and context, is another hurdle (Di Stefano & Spence, 2022). The development of standardized in silico oral processing models that can reliably predict the dynamic changes occurring during mastication for a wide range of food types is crucial. Furthermore, bridging the gap between the physics of food breakdown and the neurobiology of perception – quantitatively linking stress/strain patterns or aroma concentration profiles to neural firing and perceived attributes – is a grand challenge requiring interdisciplinary collaboration.

Conclusion

Computational gastrophysics is rapidly evolving from a niche academic pursuit to a vital enabling science for the future of food. By developing and integrating sophisticated simulation tools for flavor perception and texture dynamics, researchers are paving the way for the rational design of novel food structures that can meet specific sensory, nutritional, and sustainability targets. The convergence of multiscale modeling, advanced manufacturing techniques like 3D printing, and AI promises a new paradigm in food innovation where desired sensory experiences can be engineered from the ground up.

Future research should focus on developing more comprehensive and validated models that couple fluid dynamics, solid mechanics, mass transport, and sensory response. This will involve close collaboration between physicists, material scientists, food chemists, sensory scientists, and engineers. Speculatively, we might envision a future where "flavor algorithms" and "texture codes" allow for the precise digital specification of food experiences. Open problems include the development of high-throughput experimental methods for model validation, the creation of extensive databases of food material properties, and the incorporation of individual variability in sensory perception into predictive models. As these challenges are addressed, computational gastrophysics will undoubtedly play a transformative role in shaping how we create, experience, and think about food.

References

- Avila-Sierra, A., Bugarin-Castillo, Y., Glumac, M., Bussiere, J., Saint-Eve, A., Mathieu, V., Kobayashi, Y., & Ramaioli, M. (2024). A first-of-its-kind 3D biomimetic artificial mouth capable of reproducing the oral processing of soft foods. Scientific Reports. https://doi.org/10.1038/s41598-024-73629-9

- Derossi, A., Spence, C., Corradini, M. G., Jekle, M., Fahmy, A. R., Caporizzi, R., Devahastin, S., Moses, J. A., Le-Bail, A., Zhou, W., Zhang, M., Bhandari, B., & Severini, C. (2024). Personalized, digitally designed 3D printed food towards the reshaping of food manufacturing and consumption. npj Science of Food. http://dx.doi.org/10.1038/s41538-024-00296-5

- Di Stefano, N., & Spence, C. (2022). Roughness perception: A multisensory/crossmodal perspective. Attention, Perception, & Psychophysics. http://dx.doi.org/10.3758/s13414-022-02550-y

- Ghosheh, M., Ehrlich, A., Fischer, A., Pasitka, L., Cohen, M., & Nahmias, Y. (2024). Metamaterial-based injection molding for the cost-effective production of whole cuts. Nature Communications. http://dx.doi.org/10.1038/s41467-024-54939-y

- Hamza, Z. K., Abosereh, N. A., Salim, R. G., El-Sayed, A. F., & Aly, S. E. (2025). Unraveling the antifungal and aflatoxin B1 inhibitory efficacy of nano-encapsulated caraway essential oil based on molecular docking of major components. Scientific Reports. http://dx.doi.org/10.1038/s41598-025-95557-y

- Liu, Y., Chen, L., Hong, R., Dong, X., Sha, W., Jin, Z., Wu, T., & Chen, G. (2025). A survey of mastication evaluation: from traditional approach to artificial intelligence. Food, Nutrition and Health. http://dx.doi.org/10.1007/s44403-025-00029-w

- Mouritsen, O. G. (2012). The emerging science of gastrophysics and its application to the algal cuisine. Flavour. http://dx.doi.org/10.1186/2044-7248-1-6

- Ransmark, E., Sørensen, H., Gómez Galindo, F., & Håkansson, A. (2025). Break-Up of Plant Cell Structures in High Pressure Homogenizers – Prospects and Challenges for Processing of Plant-Based Beverages. Food Engineering Reviews. http://dx.doi.org/10.1007/s12393-025-09397-7

- Siddique, A., Gupta, A., Sawyer, J. T., Huang, T.-S., & Morey, A. (2025). Big data analytics in food industry: a state-of-the-art literature review. npj Science of Food. http://dx.doi.org/10.1038/s41538-025-00394-y

- Wang, Y., Zhao, Y., Li, B., Yang, Y., Ning, C., Wang, X., Zhang, Q., Chai, G., & Yang, C. (2025). Molecular structure characteristics and pyrolytic volatiles of hydrosoluble colored fractions from three melanoidins. Scientific Reports. http://dx.doi.org/10.1038/s41598-025-02108-6

- Xu, J., Zhang, Y., Huo, H., Qi, D., Dong, X., Tian, L., Liu, C., & Cao, Y. (2025). Integrated omics reveal the mechanisms underlying softening and aroma changes in pear during postharvest storage and the role of melatonin. BMC Plant Biology. http://dx.doi.org/10.1186/s12870-025-06714-4