Closed-Loop Autonomous Systems for Accelerated Materials Discovery: Integrating Robotic Synthesis, In-Situ Characterization, and AI-Driven Hypothesis Generation

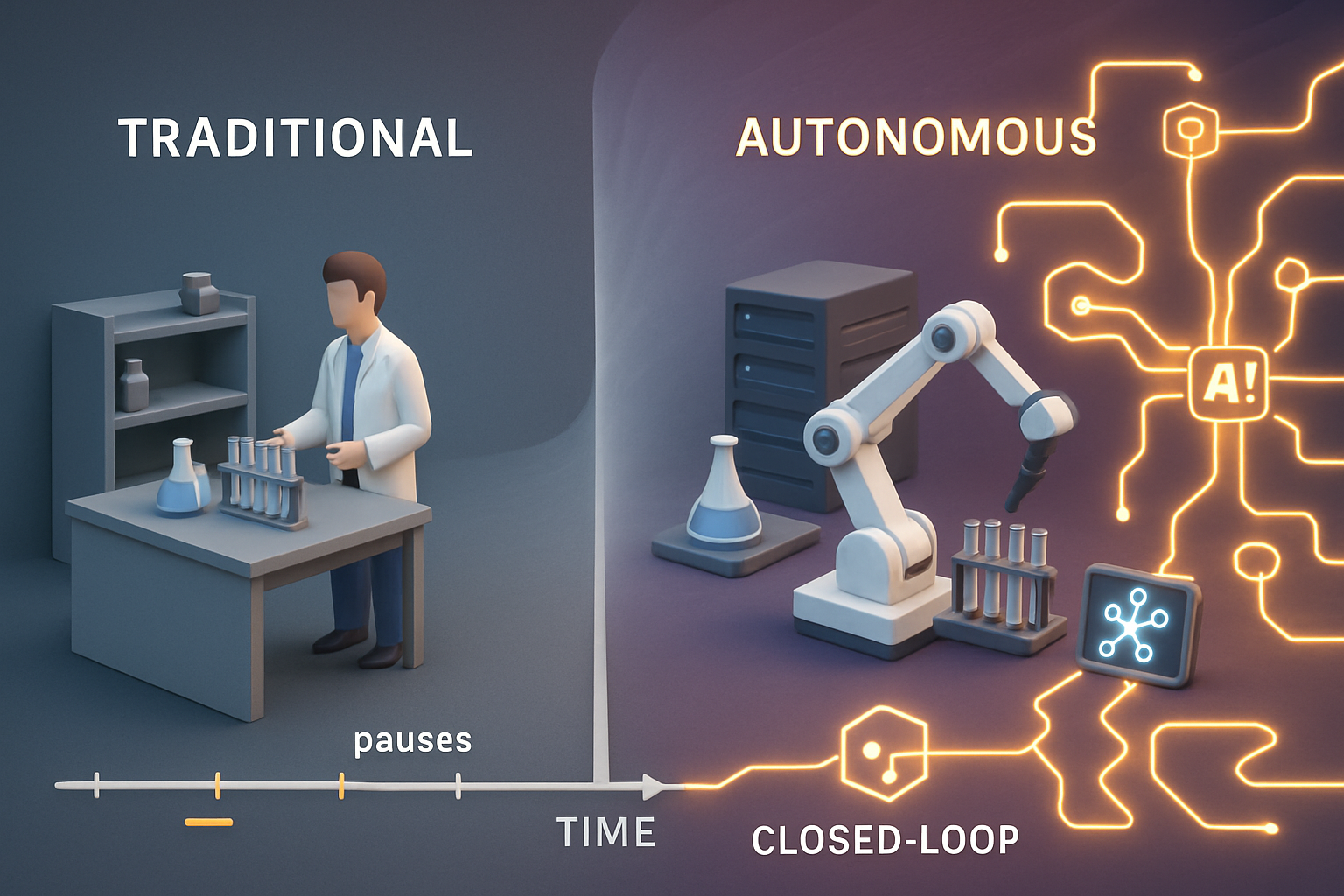

The discovery of advanced materials has historically been the engine of human progress, from the Stone Age to the Silicon Age. However, the traditional process of materials discovery is notoriously slow, expensive, and reliant on a combination of intuition, serendipity, and painstaking trial-and-error. In a world facing urgent challenges in energy, climate, and health, this protracted timeline is a critical bottleneck. A new paradigm is emerging to shatter this limitation: the closed-loop autonomous system, often termed a “self-driving laboratory.” This approach integrates robotic automation for materials synthesis, advanced in-situ characterization for real-time analysis, and artificial intelligence (AI) to form a continuous, autonomous loop of hypothesis, experimentation, and learning. By creating an automated ecosystem where an AI can design, execute, and interpret its own experiments, these systems promise to accelerate the pace of discovery by orders of magnitude. This article will dissect the architecture of these autonomous labs, explore the AI-driven strategies that enable their efficiency, and propose a forward-looking vision where these systems evolve from mere optimizers to true engines of novel material creation.

The Anatomy of a Self-Driving Laboratory

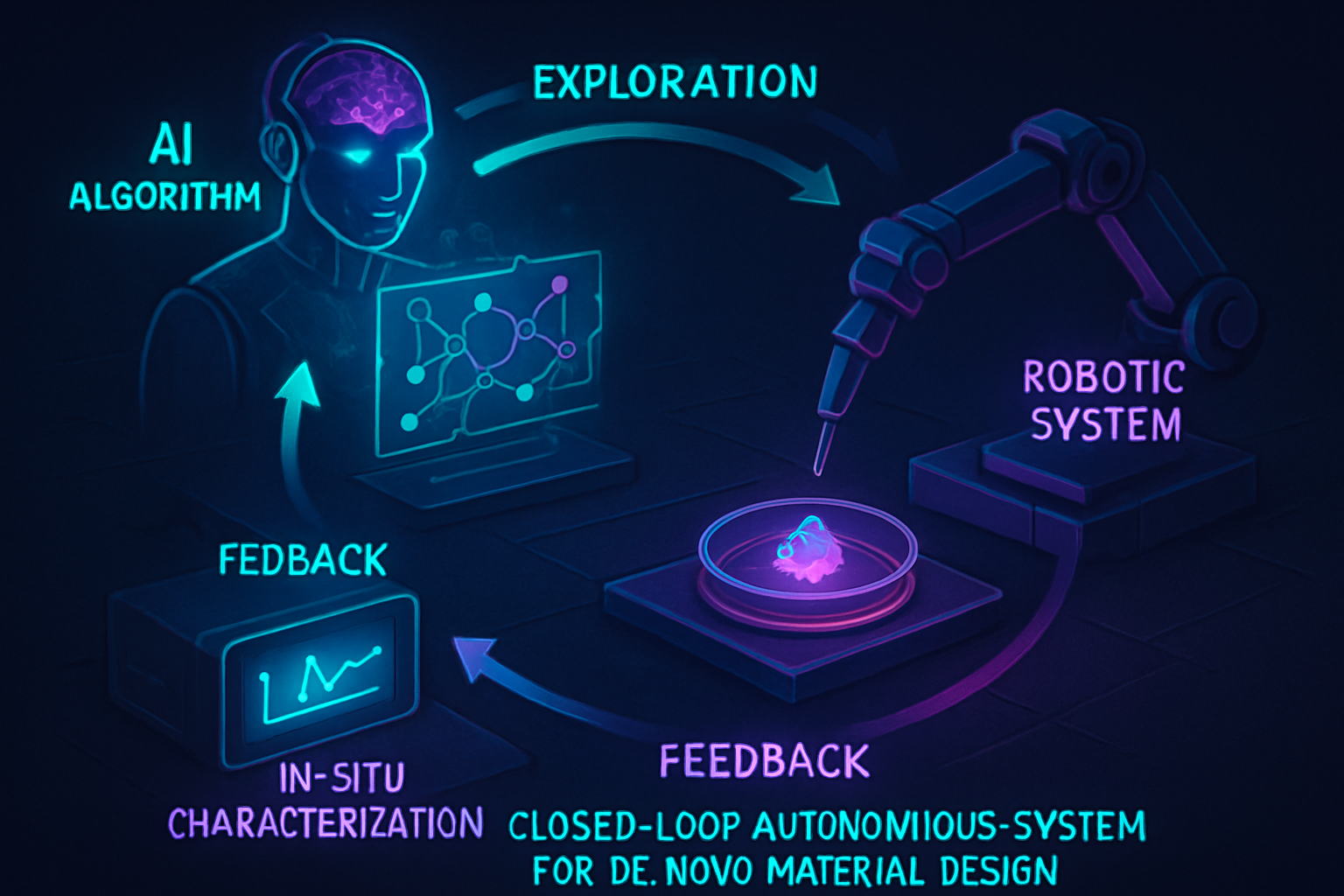

A self-driving laboratory (SDL) is not a single technology but a tightly integrated system of three core components, each performing a role analogous to a human researcher. The successful orchestration of these parts, as exemplified by software frameworks like IvoryOS which provides an interoperable interface for diverse SDLs (Zhang et al., 2025), is critical to creating a seamless discovery workflow.

The first component is the robotic synthesis platform—the system’s “hands.” These automated platforms perform the physical creation of materials with a precision and throughput unattainable by humans. They can encompass a wide array of techniques, from the robotic synthesis of multicomponent mesocrystals (Valadi Palliyalil & Ullattil, 2025) to advanced 3D printing methods like robocasting and stereolithography for creating complex scaffolds (Álvarez-Chimal et al., 2024). By automating synthesis, these platforms eliminate human variability, enable operation in extreme environments, and allow for the systematic exploration of vast, high-dimensional parameter spaces that would be manually intractable.

The second component is integrated in-situ characterization—the system’s “senses.” Traditional discovery involves synthesizing a sample and then moving it to separate equipment for post-mortem analysis. In an SDL, characterization tools are integrated directly into the synthesis workflow, providing real-time data on a material’s properties as it is being formed. This feedback can include various spectroscopic, microscopic, or electrochemical techniques, such as the electrochemical impedance spectroscopy used to probe battery systems (Bakenhaster & Dewald, 2025). This immediate, high-fidelity data stream is the crucial input that allows the AI to make informed, on-the-fly decisions.

The final, and most critical, component is the AI-driven decision engine—the system’s “brain.” This is typically a machine learning algorithm that analyzes the stream of data from the in-situ characterization tools to guide the subsequent actions of the robotic synthesizer. The AI builds an internal model of the relationship between synthesis parameters and material properties. It then uses this model to intelligently select the next experiment most likely to lead to a desired outcome. This replaces a random or brute-force search with a highly focused, statistically guided exploration, forming the core of the closed-loop discovery process.

From Intelligent Search to de novo Design

The primary power of a closed-loop system lies in its ability to navigate the immense search space of potential materials with unparalleled efficiency. Instead of a human researcher designing a static, predefined set of experiments, the AI dynamically adapts its strategy. Algorithms such as Bayesian optimization or reinforcement learning are used to balance “exploration” (testing completely new parameters to reduce uncertainty) with “exploitation” (refining parameters in a promising region of the search space). This AI-guided search can rapidly converge on optimal materials compositions or synthesis protocols while minimizing the number of costly and time-consuming experiments.

However, the paradigm is evolving beyond simply optimizing known material systems. The integration of powerful generative AI models is enabling the de novo design of entirely new materials and molecules. For example, recent work has demonstrated denoising diffusion-based pipelines that can design novel, high-affinity macrocyclic peptide binders against protein targets from scratch, with computational models closely matching experimentally determined structures (Rettie et al., 2025). This represents a profound shift from finding the best recipe using existing ingredients to inventing a new recipe and new ingredients simultaneously. The AI is not just searching a pre-defined space but is actively generating novel candidates that may possess fundamentally new structures and functionalities.

The Next Frontier: AI-Guided Emergence Engineering

We propose that the next evolutionary step for autonomous discovery systems is a move from goal-oriented optimization to what can be termed “AI-Guided Emergence Engineering.” Current SDLs are typically tasked with finding a material that maximizes a predefined target property, such as conductivity, catalytic activity, or hardness. While powerful, this approach confines the system to discovering what we already know to ask for. Emergence Engineering would instead task the AI with a more abstract goal: to find regions of the synthesis parameter space that produce novel and unexpected physical phenomena.

In this speculative framework, the AI would not be optimizing for a single metric. Instead, it would use unsupervised or self-supervised learning models to analyze the high-dimensional data from in-situ characterization, searching for anomalies, emergent patterns, or signatures that its internal models cannot explain. Upon detecting such a “region of emergent behavior,” the AI would autonomously pivot its experimental campaign to intensely probe this unforeseen phenomenon. Its objective would shift from finding a “better” material to understanding a “different” one. This flips the scientific method on its head; instead of a human formulating a hypothesis about a potential new material, the AI would discover a new phenomenon and then generate the data needed for a human to formulate a new hypothesis about the underlying physics.

This approach leverages the ability of AI to identify subtle correlations and patterns in complex data that are invisible to human perception. It moves the role of the AI from a highly efficient lab technician to a true discovery partner, pointing researchers toward the “unknown unknowns” in the materials landscape. This could be particularly powerful for discovering materials with complex, emergent properties like novel topological states, unconventional superconductivity, or self-organizing behaviors, whose discovery has traditionally relied on serendipity.

Conclusion

Closed-loop autonomous systems represent more than just an acceleration of existing research methods; they herald a fundamental change in the nature of scientific discovery itself. By integrating robotic synthesis, in-situ characterization, and AI-driven hypothesis generation, these systems are compressing the discovery timeline from years to days. The immediate challenge, as noted by developers of platforms like IvoryOS (Zhang et al., 2025), is creating standardized, interoperable software and hardware to make these complex systems more accessible. However, as these hurdles are overcome, the scientific community will be equipped with a powerful new tool. Looking forward, the shift towards AI-Guided Emergence Engineering could empower these systems to move beyond optimizing the known and begin to systematically unveil the unknown, discovering and creating novel classes of materials with properties we have not yet conceived. This new era of autonomous discovery holds the key to solving some of humanity's most pressing technological challenges.

References

- Álvarez-Chimal, R., et al. (2024). A Review of 3D Printing by Robocasting and Stereolithography for Cartilage and Ocular Tissue Regeneration. Biomedical Materials & Devices. https://doi.org/10.1007/s44174-024-00254-5

- Bakenhaster, S. T., & Dewald, H. D. (2025). Electrochemical impedance spectroscopy and battery systems: past work, current research, and future opportunities. Journal of Applied Electrochemistry. https://doi.org/10.1007/s10800-025-02273-6

- Kessels, B. M., et al. (2025). AI-based state extension and augmentation for nonlinear dynamical first principles models. Nonlinear Dynamics. https://doi.org/10.1007/s11071-025-11092-5

- Kuai, H., et al. (2025). Web Intelligence (WI) 3.0: in search of a better-connected world to create a future intelligent society. Artificial Intelligence Review. https://doi.org/10.1007/s10462-025-11203-z

- Rettie, S. A., et al. (2025). Accurate de novo design of high-affinity protein-binding macrocycles using deep learning. Nature Chemical Biology. https://doi.org/10.1038/s41589-025-01929-w

- Swensen, A. C., et al. (2025). Increased inflammation as well as decreased endoplasmic reticulum stress and translation differentiate pancreatic islets from donors with pre-symptomatic stage 1 type 1 diabetes and non-diabetic donors. Diabetologia. https://doi.org/10.1007/s00125-025-06417-3

- Valadi Palliyalil, A., & Ullattil, S. G. (2025). TiO2 mesocrystals: recent progress in synthesis, structure, and photocatalytic applications. Advanced Composites and Hybrid Materials. https://doi.org/10.1007/s42114-025-01324-y

- Zhang, W., et al. (2025). IvoryOS: an interoperable web interface for orchestrating Python-based self-driving laboratories. Nature Communications. https://doi.org/10.1038/s41467-025-60514-w