Atomically Precise Manufacturing and the Dream of a Post-Scarcity Civilization

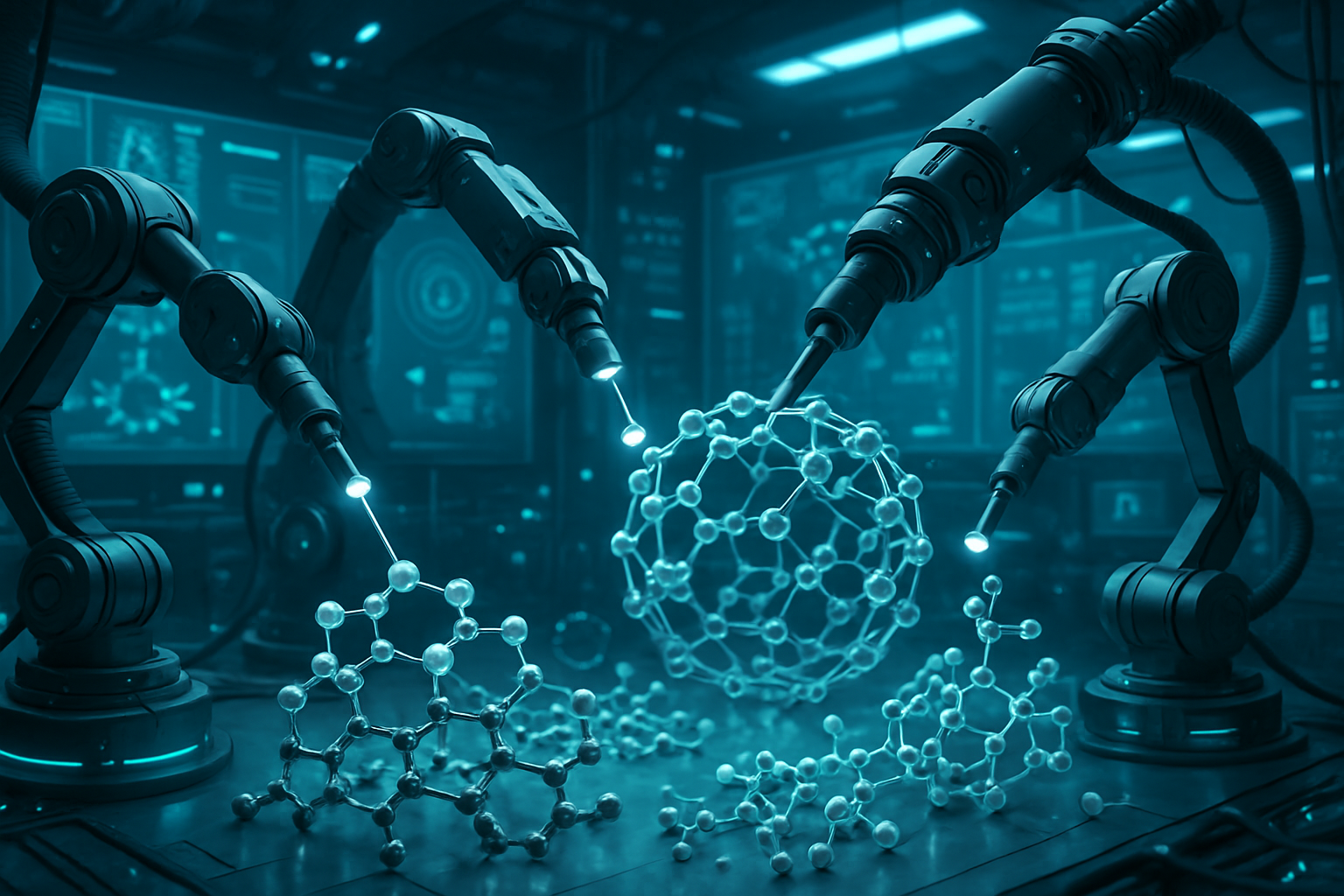

Since the dawn of civilization, humanity has been shaped by the challenge of scarcity—limited resources and the struggle for access to food, materials, and energy. However, as technology progresses, we edge closer to a remarkable paradigm shift: the end of scarcity through atomically precise manufacturing (APM). This vision, once confined to the pages of science fiction, now finds grounding in research advances such as DNA origami, nanoimprint lithography, and direct atomic fabrication. If realized, APM could enable the creation of any material or product from the bottom up, atom by atom, with near-perfect efficiency and minimal waste. Such capabilities promise to disrupt not only manufacturing but also global economics, resource management, and social organization—heralding what some futurists call a “post-scarcity” civilization.

In this article, we explore the frontier of atomically precise manufacturing, survey the latest breakthroughs, and imagine the broader implications of a world where abundance replaces scarcity. From nanotechnology labs to economic models reshaped by limitless production, the dream of a post-scarcity future appears tantalizingly within reach.

The Path to Atomically Precise Manufacturing

The core of APM lies in assembling matter with atomic precision—a level of control found routinely in nature (as seen in cellular machinery and DNA replication) but only recently achievable in the laboratory. One of the leading approaches to APM is DNA origami, a technique where DNA strands are folded into predetermined shapes at the nanoscale. As reviewed by Dey et al. (2021), DNA origami methods allow researchers to template and build nanostructures with intricate three-dimensional architecture, offering unprecedented control over functional components for electronics, photonics, molecular machines, and catalysis. While challenges remain—such as scaling up, maintaining long-term stability, and cost-effective synthesis—the field is rapidly evolving, with “next-generation” strategies focusing on in vivo synthesis and integrating biological and inorganic materials.

Another essential pillar is scalable nanoimprint manufacturing, as explored by Choi et al. (2023) in the creation of multilayered optical metasurfaces. Nanoimprint lithography (NIL) offers nanometer precision and high throughput, addressing the critical challenge of translating nanofabrication from the lab to industrial scales. The ability to fabricate complex, multilayer materials over large areas opens the door to real-world applications, from advanced computing to ultra-compact optics.

The most direct realization of atom-by-atom fabrication was demonstrated by Jesse et al. (2017), who used an electron beam with real-time feedback to manipulate silicon at the atomic level—growing and shaping crystalline regions within a semiconductor. Such breakthroughs mark the initial steps toward universal atomically precise assemblers: theoretical machines capable of engineering materials and devices with every atom in its intended place.

Economic and Societal Implications: Toward Abundance?

The march toward APM raises profound questions about economics and social structure. In a world where virtually any object can be built from abundant raw materials—recycled waste, carbon from the atmosphere, sand from the desert—conventional concepts like cost, value, and ownership could require radical revision.

Thermodynamic models of economic innovation (Garrett, 2013) suggest that the prosperity and longevity of civilizations are fundamentally tied to their capacity to harness energy and diffuse matter efficiently. If APM allows for the utilization of ubiquitous resources and the near-elimination of material waste, the physical constraints that have historically limited growth and created competition could vanish. Infinite or exponential economic growth—discussed as both a blessing and a challenge by Shkliarevsky (2022)—reaches new plausibility when resource production becomes decoupled from physical scarcity.

In a post-scarcity scenario, the structure of motivation and distribution in society might change profoundly. There would be diminishing incentive for conflict over basic needs, and collective efforts could focus on exploration, creativity, and knowledge generation. Yet, the transition would also come with risks: unemployment or social disruption among those whose jobs are rendered obsolete, concentration of power among those who control APM infrastructure, and new threats in the form of advanced but potentially misused technologies. These concerns parallel contemporary debates around artificial intelligence, as surveyed by Nelson et al. (2023), where societal impact depends not just on technical discoveries but on policy, governance, and ethical choices.

From Laboratory to Civilization: Challenges and the Road Ahead

While the promise of APM is immense, formidable technical and practical obstacles must be addressed before a post-scarcity age can materialize.

- Scalability & Integration: Current successes in atomic-scale manufacturing have tended to be small in scope—building nanostructures, not yet megastructures or mass consumer goods. Advances in scalable techniques like nanoimprint lithography and modular, self-assembling systems must converge. Shared, distributed, and cloud-based models of manufacturing (Ivkić et al., 2025; Jiang & Li, 2019) hint at how APM might eventually permeate everyday production, with Manufacturing-as-a-Service approaches leveraging local resources and reducing environmental impacts.

- Resource and Energy Considerations: While APM could, in theory, recycle materials endlessly and use common atoms from air and earth, the energy requirements for atom-by-atom assembly might still be significant. Sustainable sources of power and innovations in process efficiency will be vital to realize large-scale, environmentally benign manufacturing.

- Social, Legal, and Ethical Systems: Even with universal abundance, the distribution of access, the prevention of misuse (for example, weapons), and the management of intellectual property and innovation incentives will require careful, perhaps novel, regulatory structures and cultural adaptations.

- Interfacing with Nature: DNA origami and biological APM may allow us to blend artificial and natural systems in health, environment, and agriculture—extending post-scarcity principles beyond human society to the biosphere itself.

Conclusion: The Shape of Tomorrow

The ongoing quest for atomically precise manufacturing represents not just a technological pursuit, but a transformation of the human condition. The road from laboratory nanostructures to a post-scarcity civilization is steep and filled with both promise and peril. Recent breakthroughs demonstrate that the physical tools for such an era—where “stuff” is limited only by imagination and energy—stand on the threshold of possibility.

The transition will demand profound shifts in our economics, laws, and values, requiring collective stewardship and creativity. If we manage the transformation responsibly, APM could mean scarcity becomes a relic, and the basic needs of all may one day be met with abundance and dignity. The future, atom by atom, is before us.

References

- Choi, S., Zuo, J., Das, N., Yao, Y., & Wang, C. (2023). Scalable nanoimprint manufacturing of multi-layer hybrid metasurface device. https://arxiv.org/abs/2312.14297

- Dey, S., Fan, C., Gothelf, K. V., et al. (2021). DNA origami. https://arxiv.org/abs/2104.15016; Nature Reviews Methods Primers 1, Article number: 13 (2021).

- Jesse, S., Hudak, B. M., Zarkadoula, E., et al. (2017). Direct atomic fabrication and dopant positioning in Si using electron beams with active real time image-based feedback. https://arXiv:1711.05810

- Garrett, T. J. (2013). Thermodynamics of long-run economic innovation and growth. https://arXiv:1306.3554

- Shkliarevsky, G. (2022). Infinite Growth: A Curse or a Blessing? https://arXiv:2201.09806

- Nelson, J. P., Biddle, J. B., & Shapira, P. (2023). Applications and Societal Implications of Artificial Intelligence in Manufacturing: A Systematic Review. https://arXiv:2308.02025

- Ivkić, I., Buhmann, T., & List, B. (2025). A Cost-Benefit Analysis of Additive Manufacturing as a Service. https://arXiv:2502.05586

- Jiang, P. & Li, P. (2019). Shared factory: a new production node for social manufacturing in the context of sharing economy. https://arXiv:1904.11377